Bury Standard 4 Group - Restoring 80097 and 46428

become a supporter, see how you can help learn more...

Browse now and find out more, and support us today.

Your basket is empty

Bury Standard 4 Group - Restoring 80097 and 46428

become a supporter, see how you can help learn more...

Your basket is empty

Tuesday, 1st December, 2015

Alan, Jeff and Dan have fitted a tool board to the back of the workbench and Alan has mounted the tool discs to it and rearranged the bench layout.

Dave and Jimmy have collected the delivered 5 metre lengths of steel main steam pipe from Baron Street – an absolute epic. The first length has been cut to size, filled with sand and ends welded onto it ready for bending.

Nigel has fitted the components for the blowdown lever and then assembled the fireman’s seat components. He then shaped the wood for the seat.

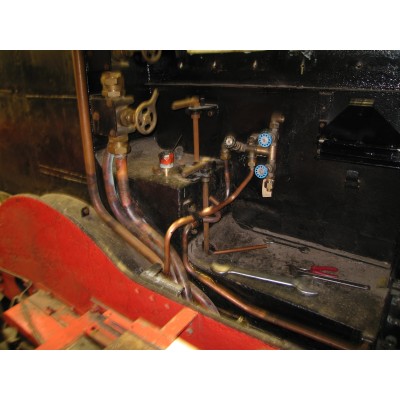

Allan has completed the bending and fitting of the feed pipe from the injector to the fireman’s controls. He then silver soldered the fittings onto the steam chest pipe.

Harry and Dave have been working between the frames and checking all the pipe clamp mountings and fitting spring washers and split pins.

Jeff has started turning pins for the lifting frame, assisted by Jimmy.

Nigel B is continuing to make studs for the superheater header.

Stuart has now finished the welding of the cladding bands, which Hughie has painted and these have now been fitted to the crinolines for storage. Stuart then continued with the cleaning and waxoyling of the linkages and motion.

Allan and Dan connected the fireman’s side oil pump linkage.

With the leadership of ‘Magic Andy’, Allan, Nigel, Jimmy and Harry have managed to bend the two main steam pipes in one piece. These now need final profiling and the fitting of the end bosses.

Pictures are :

Welding the crinoline bands

Fireman's controls piping

Bending the main steam pipes